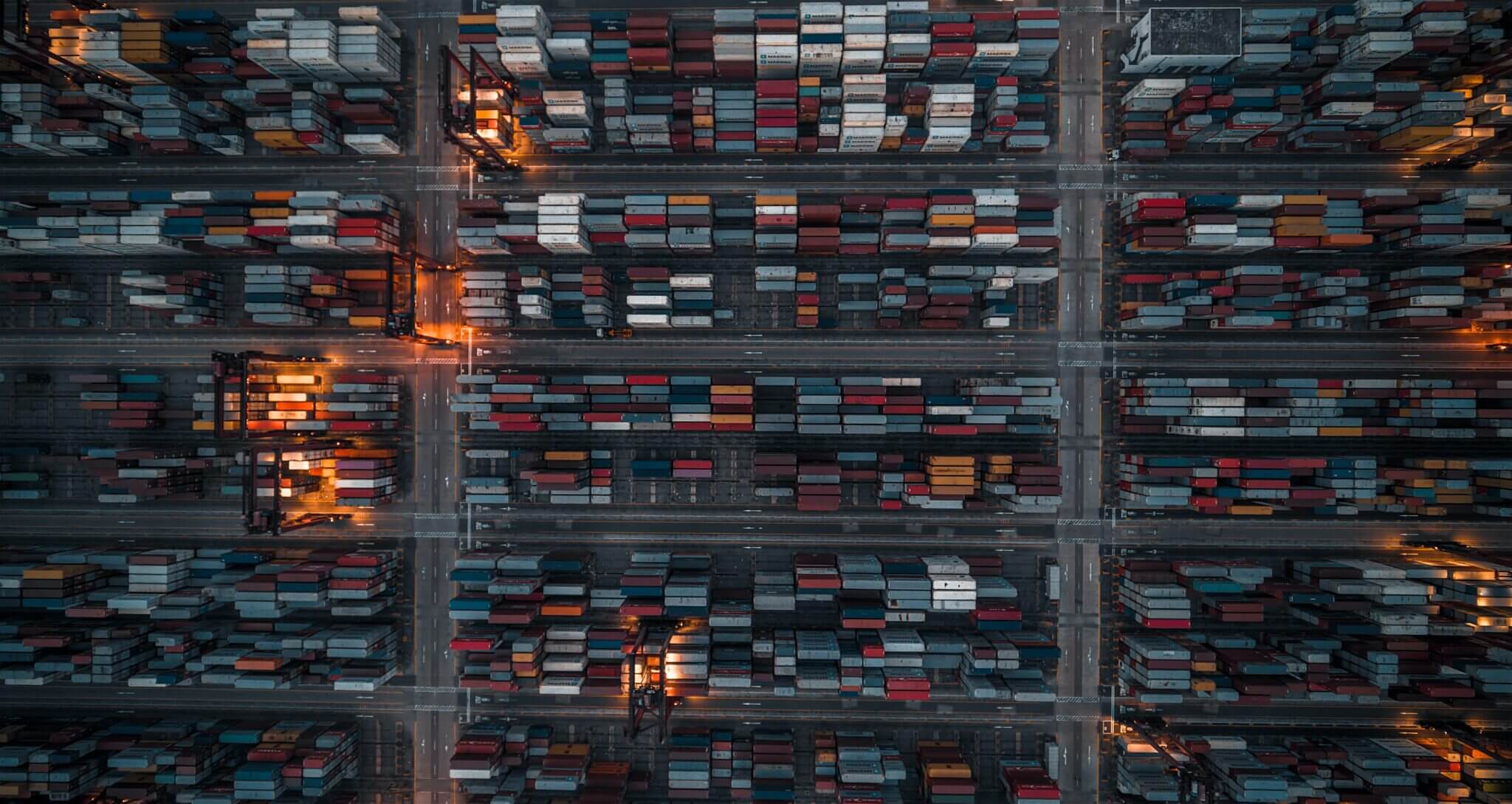

There is mounting evidence of an unprecedented global supply chain crisis stemming from an uneven economic recovery as demand revives in the wake of a subsiding pandemic, that has hit many countries hard as they struggle to cope with bottlenecks and shortages of workers and goods.

Few of us ever give much thought to supply chains: they usually function well, with a constant flow of products being moved by ships, planes, trains and trucks, and that depend on millions of workers who pack, move, load and unload them. The problem now comes from industries that in many cases have been particularly hard hit by the pandemic, in countries still struggling to cope with Covid, and that are generating major inventory strains on more and more products, seemingly unrelated to each other, other than relying on the same supply mechanisms. Every country is affected to a greater or lesser extent, and many of them now face major crises.

Some countries are undoubtedly better placed than others. While the supply chain in the United States generally depends on a multitude of interconnected systems and companies all operating independently, in many cases exclusively, so as to avoid industrial espionage, in other countries, ports are managed by fully integrated systems more akin to a homogeneous API that allows operations to be coordinated more efficiently. But at this stage of the crisis, it almost doesn’t matter: the effect of the collapse of certain nodes has spread to all links in the chain and now affects everyone.

We now see ships waiting at sea to unload in congested ports whose infrastructure has collapsed and where container prices have risen sixfold. Alternatives, such as air or rail transport, fail to alleviate the problem, and in some cases, the crisis becomes a matter of state that leads to negotiations with port workers to increase the number of hours worked to the 24×7 limit to undo ever-lengthening bottlenecks.

Supply chains are not expected to return to normal until next year, and many analysts believe that the situation will get worse before it gets better. Like a vast row of giant dominoes, these bottlenecks are forcing factories to close for lack of supplies, leaving stores with empty shelves, and many businesses in despair. There is no single sticking point: the crisis has spilled over and has affected the entire chain. It is no longer even a question of getting a container, many of which are waiting at the ports to be emptied and reshipped, but of ensuring that, if you have one, it will reach its destination and manage to be unloaded, put on a trailer and taken to its destination. No matter how much you are willing to pay to get a head start at one point in the chain, nothing ensures that the other constraints will allow the goods to be delivered, let alone that this will happen within agreed timeframes.

With the situation as it is, many businesses are not only trying to get by as best they can or to prepare for supply shortages, but are also trying to redesign their supply chains to make them more self-sufficient, favoring availability over cost. Some are opting for suppliers closer to home or within their borders, others are diversifying their sources, and others are increasing prices to meet higher costs for the components or materials they need.

An accordion effect derived from the pandemic, from factory closures in half the world and from depressed consumption during the lockdown, which has not yet been ironed out. In some places this has generated network effects that are impossible to foresee or to resolve easily. The results could range from a global economic crisis, with inflation and rising interest rates, to a radical rethink of the sourcing of many companies’ supplies, with effects that are very difficult to foresee.

Attaining more resilient and robust supply chains, less subject to occasional crises — be it a ship stuck in the middle of the Suez Canal or a global pandemic — will be the priority focus for the managers of many companies, while at the same time, the pressure to urgently decarbonize much of their logistics is becoming ever stronger. If you thought the crisis would end with the pandemic, you were wrong: we face a difficult few years ahead.